A broad and integrated selection of advanced solutions designed for industrial maintenance, including cleaning for storage tanks, pipelines, confined areas, ATEX environments, and underwater operations.

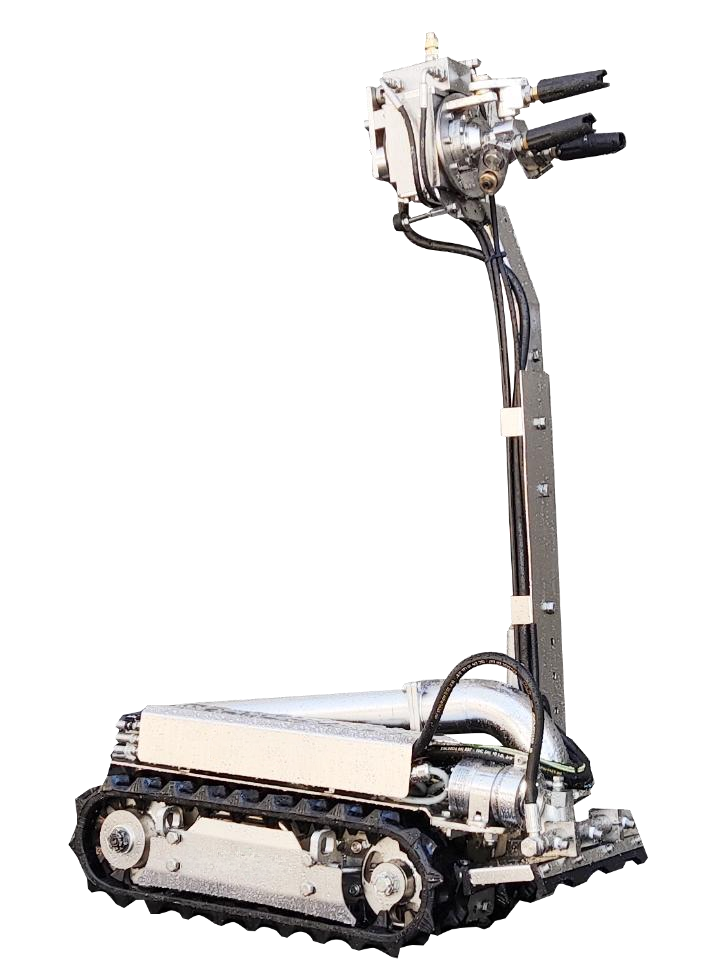

Lombrico S Atex Zone 0 Certified Robot

- Antistatic Anti-oil Chemical Resistant Rubber Tracks.

- Suction Hose 100[mm] (4") with quick couplings.

- 100mm / 4" Stainless Steel Male Camlock Coupling on the back of the machine.

- Flat Suction frontal tool 45°.

EX MARKING:

II 1G Ex h IIB T4 Ga

AMBIENT TEMPERATURE:

- 20°C ≤ T. amb. ≤ +60°C

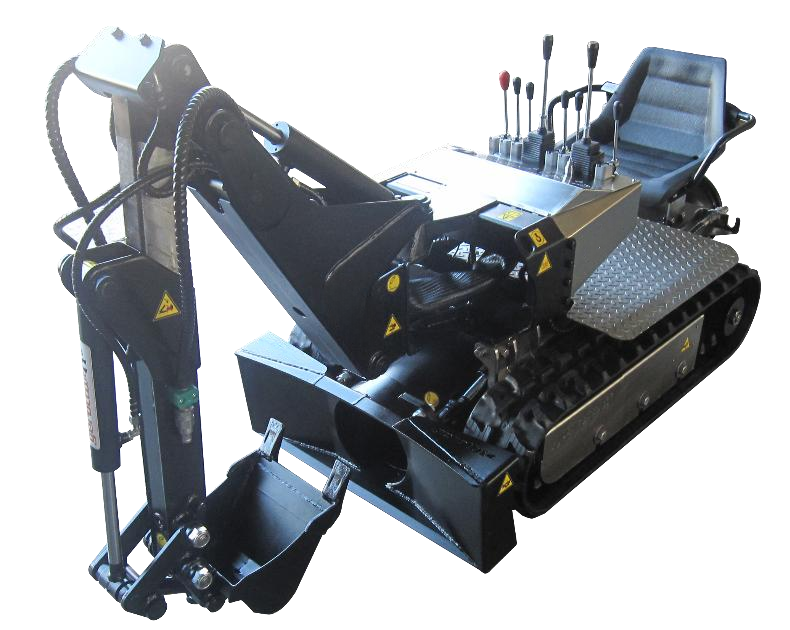

GATTO Man on Board with Suction Hose

Atex Zone 0 Certified

1) Tracked Undercarriage:

- Stainless Steel Composition.

- 2 X oil resistant Rubber Tracks.

- 2 X independent Hydraulic Motors for tracks movements.

- 1 X cylinder for frontal stabilizer blade UP/DOWN Movement.

- Galvanized Flat Face Quick Couplings (ISO 16028) on the machine for connection with umbilical connection.

2) 250 [mm] /10” Suction hose with Gerotto dry-set coupling for suction hose connection option.

3) Heavy duty carbon steel excavator power arm with hydraulic movements + one external hydraulic predisposition.

4) Carbon Steel 250 [mm] Standard Bucket with teeth.

Atex Zone 0 Certified Lombrico X

(Fuel Tank Cleaning)

Composed of:

- Stainless Steel Composition (AISI 304).

- Antistatic rubber structure.

- Oil/Chemical/Hydrocarbons resistant Composition.

- 2 x Independent Hydraulic Motors for tracks movements.

- 1 x Stainless Steel Hydraulic Cylinder for Washing Arm UP/DOWN Movement.

- 1 x Stainless Steel Hydraulic Cylinder for Suction Hood UP/DOWN Movement.

- Atex Zone 0 Water Engine for nozzles rotation.

- 3 x high pressure water nozzles for 360° tank cleaning. 65 [lt/min] – [18gpm] @ 250 [bar] – 3600 [psi].

- High pressure water nozzles for basement tank cleaning.

- 1 x spray nozzle for chemical injection.

- 3’’ / 75mm Suction Hose Connection.

- Minimum manhole ø 17’’ / 425 mm.

EX MARKING:

II 1G Ex h IIB T4 Ga

AMBIENT TEMPERATURE:

- 20°C ≤ T. amb. ≤ +60°C

100m/328ft umbilical connection between the Operator Control Station (OCS) in Atex Zone 1 and the Robot in Atex Zone 0:

- Antistatic Umbilical Connection with Quick Connection System.

- Intrinsically safe cable for CCTV and grounding system.

- Protected by an antistatic and oil resistant sleeve.

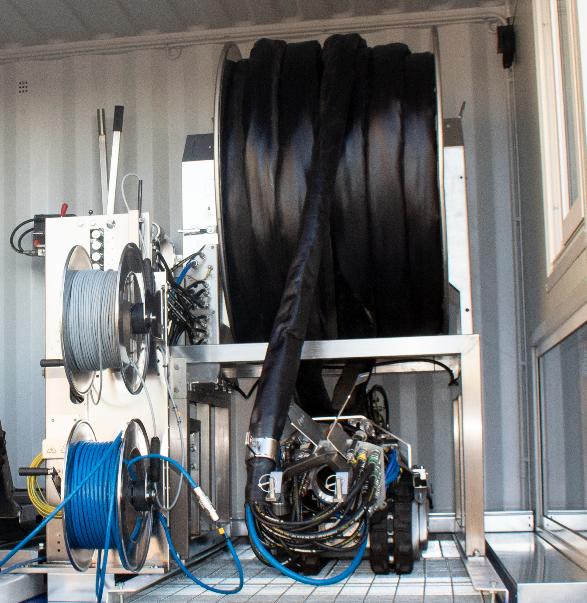

Atex Zone 1 Hydraulic hose reel or 100m umbilical connection

Designed to accommodate up to 100 meters of umbilical connection between the hydraulic control unit in Atex Zone 1 and the robot operating in Atex Zone 0:

- Complete Stainless-Steel Structure.

- Manual hydraulic command for easy rolling and unrolling of the umbilical connection.

- Manual regulation of the speed of the rotation.

- Forklift predisposition and lifting points for crane lifting.

EX MARKING:

II 2G Ex h IIB T4 Gb X

AMBIENT TEMPERATURE:

- 20°C ≤ T. amb. ≤ +60°C

Atex Zone 1 20ft marine container with ergonomic control installation

With compartments for:

- Installation of the Atex Zone 1 Hose Reel for the umbilical connection from the robot to the control station (Quoted Separately).

- Storage of the Atex Zone 0 robot (Quoted Separately).

- Storage and transportation of the manual hydraulic ramps for entering the manhole (quoted separately).

- Compartment for the Operator for controlling the complete system.

- Screen/s for Controlling the CCTV System (quoted separately).

- Desk.

- Chair.

- Atex Zone 1 Lighting System for the Operator Cabin including:

- 1. Bright white light 5500K

- 2. Red light 5500K for night shift operation.

- Atex Zone 1 Lighting system for the storage side of the container

- including external illumination of the container.

- Temperature Insulated Walls, Door and Roof for Hot/Cold Working Operation.

- Customization of the container to work with closed doors.

- Atex Zone 1 Grounding System.

- Atex Zone 1 Ergonomic Controls Installation.

- Ergonomic seat with variable height and front/rear adjustment position.

- Adjustable arm holders.

- Commands for left and right hand.

- Emergency Button and safety lever for hydraulic oil bypass.

- Doors and structure customization for ventilation.

- Doors and structure customization for operation with closed doors.

- Colour to be agreed during manufacturing.

- ISO & Marine.

- CSC certification valid for 1 year.

- Possibility for renewal the CSC Certification every 12 months.

- Installation of an access ramp for people with disabilities.

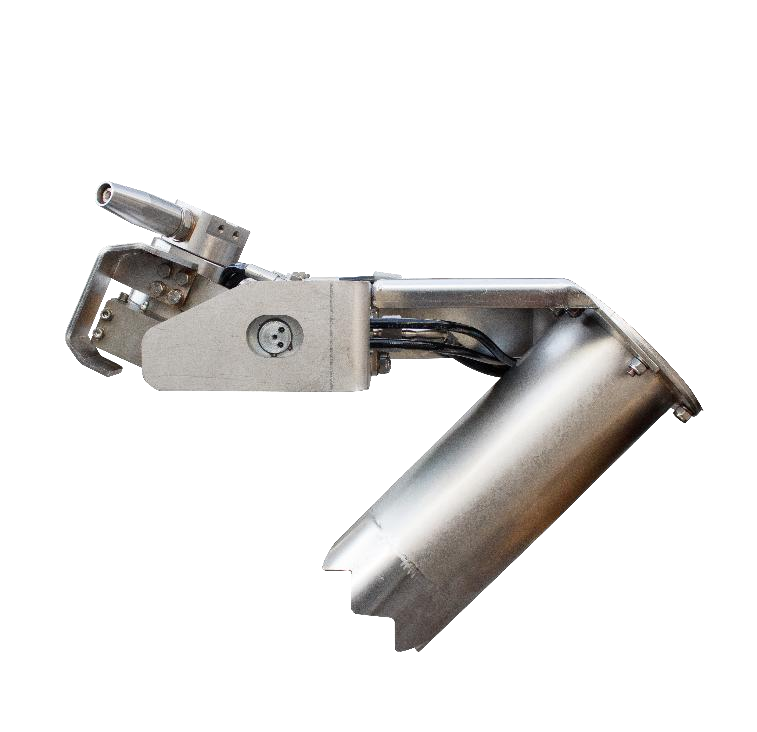

CCTV System Camera Arm

- Stainless Steel Structure.

- Stainless Steel cylinder for lifting and lowering of the camera arm.

- Suitable to enter in the 600 mm/24" manhole.

- Adjustable position during the working operations.

- Suitable to be combined with all the available CCTV systems.

- Including system modification required in the umbilical connections.

- Including system modification required in the control systems.

- Suitable to be installed on any Lombrico S robot. (*)

(*) Retrofit on existing units to be evaluated case by case.

ATEX ZONE 0 CCTV SYSTEM

Composed of:

3 Atex Zone 0 cameras, 2 Atex Zone 0 Led Lights and 2 Atex Zone 1 19” monitor.

- 3 Atex zone 0 Certified Cameras, respectively:

- 2 cameras mounted on the robot;

- 1 separated camera including 25m cable + manhole pan & tilt installation bracket.

- 2 Atex zone 0 Certified Led directional lamps.

EX MARKING:

II 1G Ex ia IIB T4 Ga

AMBIENT TEMPERATURE:

- 20°C ≤ T. amb. ≤ +60°C

- 1 Atex zone 0 electrical enclosure mounted on board of the machine.

EX MARKING:

II 1G Ex ia IIB T4 Ga

AMBIENT TEMPERATURE:

- 20°C ≤ T. amb. ≤ +60°C

- Intrinsically safe Switch Box with Led Lamps ON/OFF commands.

- 2 x Atex Zone 1 19” Monitor.

EX MARKING:

Ex II 2(1)G Ex db eb [ia Ga] IIA T5 Gb

AMBIENT TEMPERATURE:

- 20°C ≤ T. amb. ≤ +50°C

- DVR with wireless download.

- Complete with Intrinsically safe cable, wiring and connectors.

Atex Zone 0 Certified Magnetic Tracks (Pro):

- Suitable to be mounted on a Lombrico S Model.

- Antistatic Polyurethane structure.

- Oil/Chemical/Hydrocarbons resistant Composition.

- Customized Stainless-Steel Sprockets for retrofitting the existing units.

- Customized brass made guide to hold the tracks in position.

- Customized Structure adapt to be used in coated tanks, without damaging the coating.

- The kit includes 50% magnetic pads on each track plus 50% pads with no magnetic power, mounted alternately.

- Each track is composed of one magnetic pad mounted alternately with one no magnetic pad.

for L_S_EX0

HPU (Hydraulic protection unit) SIL 2 Protection Module for NON-ATEX hydraulic and electric power supplies:

- Suitable to be used in combination with Atex Zone 0 Certified Equipment.

- Hydraulic Oil Parameters PLC Control System.

- Oil pressure control system.

- Oil flow control system.

- Oil Temperature control system.

- Grounding System.

EX MARKING:

II (1) G

AMBIENT TEMPERATURE:

- 10°C ≤ T. amb. ≤ +50°C

1) 15kW Electric Three Phases 400V 50 Hz Power Unit:

- Variable Displacement Oil Pump 25-35 [lt/min]; 6.6 - 9.3 [gpm].

- Adjustable oil pressure 150-250 [bar]; 2600-3200 [psi].

- Oil coolers designed for tropical countries (15°C/ +50° C).

- Forklift predisposition and lifting points for crane lifting;

- Safety Drip Tray.

2) Hydraulic Specs:

- Adjustable oil flow.

- Hydraulic Oil tank.

- Hydraulic Oil filters.

- Hydraulic Oil level sensor.

- Easy Hydraulic Oil discharge Valve.

3) Electric Control Box:

- Basic control panel for engine parameters.

- Grounding cable connection.

Non ATEX equipment.

To be placed in safe area.

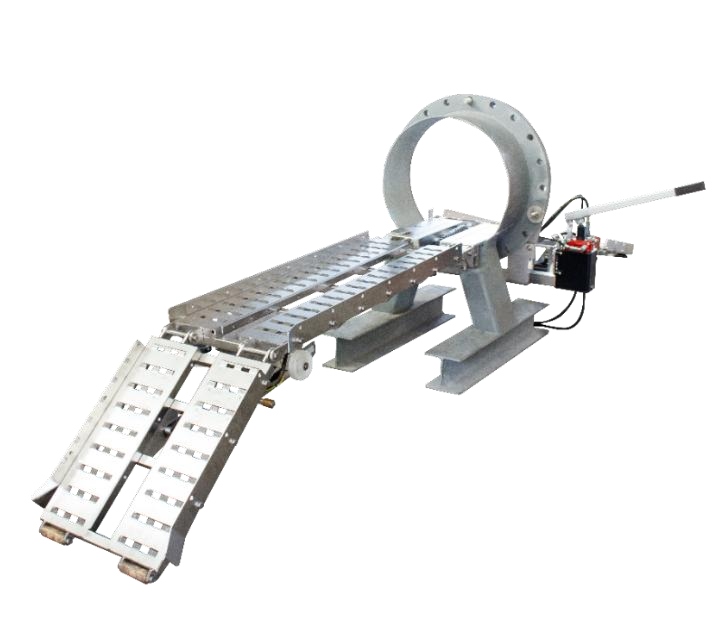

No-men-entry manual hydraulic ramps and manhole guide tool:

- Storage rack for easy handling or Suitable to be stored in a 10ft or 20ft container.

- Stainless Steel structure with anti-spark safety protections.

- Composed of three parts for easy assembly and installation.

- Grounding connection for equipotential balance and safety.

- Hydraulic manual pump for ramps operation.

- Compatibility with any manhole flange shape and dimensions.

- Roller support for umbilical connection and suction hose to be mounted on the manhole flange.

for L_S_EX0

Atex Zone 0 Certified Auger Configuration

- 4” Suction Connection with interchangeable flange.

- Screw shaped construction with interchangeable drums.

- Anti-Sparks material construction and hydraulic drums rotation.

- Stainless steel (AISI 304) safety protection for the frontal screw.

- Teflon-Made bottom profile for not damaging the tank floor coating.

For L_S_EX0

Atex Zone 0 Certified High Pressure/High Flow Water Nozzles Kit

5 X high pressure/low flow rotating water nozzles 35 [lt/min] – 9.3 [gpm] @ 400 [bar] – 5800 [psi]:

- Possibility to hold up to 700 [bar] – 10.000 [psi] of water pressure.

- Orientable position.

- Possibility to customize nozzles and water flow on request.

- Including adaptor for installation on 100mm hose.

For L_S_EX0

Atex Zone 0 Certified Combi Nozzle

- 4” Suction Connection with interchangeable flange.

- Stainless Steel Piston for frontal opening.

- 3 X high pressure fan water nozzles; 45 [lt/min] - 11.8 [gpm] @ 400 [bar] - 5800 [psi].

- Teflon-Made bottom profile for not damaging the tank floor coating.

for L_S_EX0

Atex Zone 0 Certified Squeegee tool

- 4” Suction Connection with interchangeable flange.

- Suction point in the middle of the tool.

- Stainless steel structure.

- 2 X Stainless steel cylinders for lateral opening and closing.

- Possibility to configure it in two different arms lengths (short and long).

- Antistatic and Oil resistant rubber protections for tank floor and walls.

- Suitable to be used in combination with Atex Zone 0 High Pressure/High Flow Water Nozzles Kit.

for L_S_EX0

Atex Zone 0 Certified Stainless-Steel Counterweights

30Kg each part for a total of 120Kg.

Stainless Steel AISI 304 Composition.

2 X Counterweights per side with a Screw-Connection System.

Atex Zone 0 Certified High Flow Hydrant Tool

- 300 [lt/min] @ 200 [bar] - 80 [gpm] @ 2900 [psi].

- Two axles of rotation with hydraulic actuators.

- Stainless Steel 304 Structure.

- Water Nozzle included.

- Only water spraying available on the tool, no suction.

- Suitable to be installed on any Lombrico S robot (*).

- Including adaptor for installation on 100mm hose.

for L_S_EX0

Atex Zone 1 Certified Hydraulic Hose Reel for Suction Hose

- Stainless Steel Structure.

- Forklift and lifting points for easy handling.

- Suitable to be installed in a 10ft or 20ft container.

- Suitable to hold up to 80m of 4” suction hose.

- Hydraulic Manual Lever Command for Rolling and Unrolling the hose reel.

- Suction Hose not included in the Supply.

EX MARKING:

II 2G Ex h IIB T4 Gb X

AMBIENT TEMPERATURE:

- 20°C ≤ T. amb. ≤ +60°C

Extra CCTV IS cable with connectors (25 m) for any Camera installation on the manhole

25m of Intrinsically safe cable to enlarge the connection between the manhole camera and the control station (from 25m to 150m).

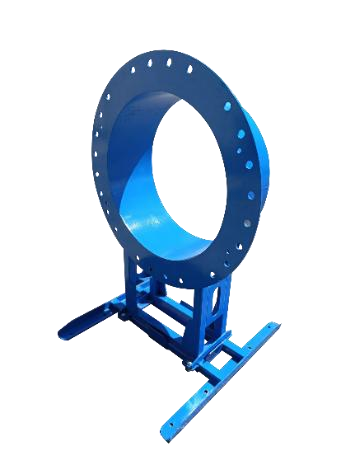

Fake manhole for training purpose

Gerotto 4" / 100mm flexible suction hose with:

- Internal galvanized steel spiral;

- External spiral in stainless steel;

- Internal layer in POLYPROPYLENE;

- External cover in special anti-abrasive PVC fabric;

- Resistant to atmospheric agents.

- One section of 40 meters;

- Connections at the end to be agreed during manufacturing.

- Bending Radious: 300mm

- Weight: 3,10 Kg/m

- On both sides connected 4” BSPT MALE THREAD in AISI316 Stainless Steel

- fittings in stainless steel and sealing gasket between hose and fittings in NBR.

- Declaration 2014/68/EU “PED”

- Declaration of conformity to the European directive 2014/34/EU “ATEX” complete with marking with: ATEX LOGO – TECH FILE – PIPE TYPE – PIPE CLASS

- Material certificate EN10204-3.1

- Visual and dimensional inspection

- Hydraulic test at 10.5 bar pressure

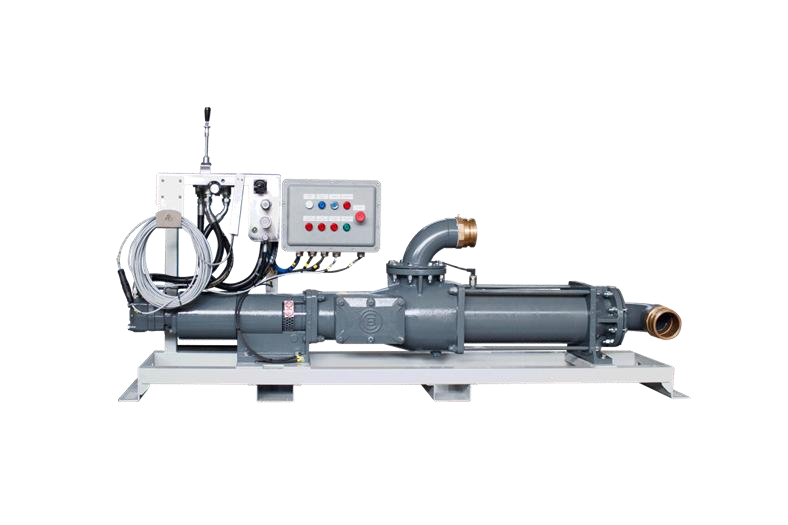

SCREW_PUMP_EX1

- Atex Zone 1 Certified

- Speed (rpm): 250 rpm

- Capacity (water at 20°C): ~ 50 mc/h (± 5%)

- Working pressure (bar): ~ 2 bar

- Suction (mt): ~ 60 mt (horizontal)

- Direction of rotation: counterclockwise as seen from the pump drive shaft

Included:

- Electrical system for temperature sensor;

- Atex electrical panel to be placed in control room for temperature sensor management;

- Dedicated bypass valve for the control unit circuit.

EX MARKING:

II2GD T4 T135°C

ATEX ZONE ONE HYDRAULIC MOTOR

25m/82ft umbilical connection for the PUMP:

- 3 X Hydraulic Hoses.

- 1 X electric cable.

- Protected by an antistatic and oil-resistant sleeve.

2pcs:

- 1 between the power unit and control room;

- 1 between the pump and control room.

1) 22kW Electric Three Phases 400V 50 Hz Power Unit:

- Variable Displacement Oil Pump 45-60 [lt/min]; 12 - 16 [gpm].

- Adjustable oil pressure 150-250 [bar]; 2600-3200 [psi].

- Oil coolers designed for tropical countries (-15°C/+50° C).

- Forklift predisposition and lifting points for crane lifting;

- Safety Drip Tray.

2) Hydraulic Specs:

- Adjustable oil flow.

- Hydraulic Oil tank.

- Hydraulic Oil filters.

- Hydraulic Oil level sensor.

- Easy Hydraulic Oil Discharge Valve.

3) Electric Control Box:

- Basic control panel for engine parameters.

- Grounding cable connection.

Non ATEX equipment.

To be placed in safe area.

GENERATOR

Silenced version with galvanized steel sheet and powder-painted canopy, compact base frame, with bunded tank and leak control.

- Fuel Tank Capacity: lt. 160

- Prime Power (PRP): kVA 100

- Prime Power (PRP): KW 80

- Limited Power (LTP): kVA 110

- Limited Power (LTP): KW 88

- Rated Power Factor (cosφ): 0.8

- Windings: Three phases - Series Star

- Rated three-phase concatenated Voltage:

- V 400

- Rated phase-neutral voltage: V 230

- Rated frequency: Hz 50

- Fuel type: Diesel

- Length mm 2560

- Width mm 1040

- Height mm 1805

- Weight Kg 1600

- Sound pressure 7 m. dBA 65

HD VACUUM LOADING SOLIDS PUMP

- -780 CFM AIR CONFIGURATION

- -4" SUCTION INLET

- -4" DISCHARGE OUTLET

- -316 SS VESSEL

- -316 SS HEAVY DUTY RB VALVES

- -CRUSH FRAME WITH NOISE ABATEMENT

HIGH PRESSURE WATER JETTING MACHINE BASE JET 30 HOT WATER WITH CRASH FRAME

Base jet 30 500-30-95-d high pressure hot water jet system 500 bar, 30 l/min, 95 °c, diesel engine, stage 5.

1 piece crash frame "l" for base jet 30/125

1 piece radio control, 6-channel, bj/tj 15/30, easy 2, range about 100m